Approved for ATL and one man testing, the new Boston hydraulic and pneumatic Wheel Play Detectors lead the field with more features and benefits than any other units available on the market. Compared to some models, a Boston PD provides substantially more force, extra moving-plate travel and a larger plate area – all recessed into our broad platforms which are up to 30% wider than some others.

If you plan to enjoy the extra profits of one-man testing then it’s essential to install the right play-detector . . . and for sure they are NOT all the same.

A good quality play-detector will save you lots of time, reliably improve MoT tests – and only one person needed!

Approved for Class IV and VII testing, the PD302, PD303 and PD304 have many advantages, such as stylish membrane control keypads and portable robust torch controls using bright LED clusters. Our wireless rechargeable torch is also an option providing complete mobile flexibility. Furthermore, at just 45mm high, they are the most slim-line models on the market.

Select below to see further product specifications.

There are a host of standard features that put the PD304 far ahead of the field – just see the specification below.-

There are a host of standard features that put the PD304 far ahead of the field – just see the specification below.-

PD304 Wheel Play Detector Features

- Lift post or Pit mounted

- Combined lateral and rotational vehicle wheelshift from a single, compact hydraulic power unit

- Significantly exceeds the force, dimensional and functional requirements for Class IV and Class VII MoT testing

- Fast one-man inspection of wheel bearing wear and steering linkage components

- High quality, heavy duty hard wired inspection / control torch (BTC3) with the latest LED cluster technology (two versions available)

- Optional RF remote control torch avoids trailing leads for convenient and safer operation

- Auto-repeat function in all lateral and rotational modes

- Auto-zero plate centring

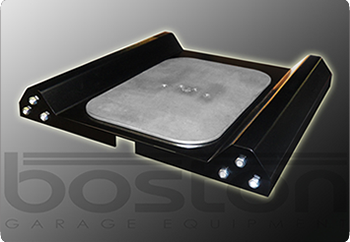

Designed for quick and simple installation in Boston lift recesses, providing a level platform

Designed for quick and simple installation in Boston lift recesses, providing a level platform- Suitable for pit testing, with frame kit for convenient installation in just 52mm deep recess

- Pit testing option includes an ‘in-pit’ connection box with secondary E-Stop and torch connection socket

- Wipe clean attractive controls with integrated LED mode indication (torch control BTC4)

- Processor controlled system with future expandability to integrate other boston hydraulic products

- Attractive chequered surface moving top plate with low friction polished underside

- Single phase operation for quick and simple installation

Technical Specification

- Power: 1 Phase 230V / 50 Hz / 13A

- Motor: 0.75 kW

- Electronics: Microprocessor Controlled

- Operating Pressure: 150 bar

- Weight and Build – Pedestal: 18 k g – Steel panel construction

- Weight and Build – Floor Unit: 45 kg – Steel construction

- Max Design Load: 1500 kg

- Floor Unit Chassis Dimensions: 605 x 600 x 45 mm [L x W x H]

- Pedestal Control Dimensions: 800 x 150 x 196 mm [L x W x H]l

- Communication: Serial / wireless FM / direct PLC connection

- Operator Control: Remote hardwired torch / RF torch

Boston’s PD-302 offers the big advantage of self-centring, automatically, instantly, accurately at the touch of a button. This saves time and ensures correct left and right movement, but importantly this feature also avoids excess one-sided travel and impact forces which are not good for the play detector, the vehicle or the lift! PD302 is powered by patented fluidic muscles which can develop ten times the initial force of same diameter air-cylinders.

Boston’s PD-302 offers the big advantage of self-centring, automatically, instantly, accurately at the touch of a button. This saves time and ensures correct left and right movement, but importantly this feature also avoids excess one-sided travel and impact forces which are not good for the play detector, the vehicle or the lift! PD302 is powered by patented fluidic muscles which can develop ten times the initial force of same diameter air-cylinders.

The advantages are extraordinary….. Instead of air cylinder problems – there are no pistons, no rods, no packing or seals, no gaskets or rings, no needles or magnets. No friction, no wear, no maintenance and just one moving part. Fascinating perfection of a bionic principle.

In standard form, the PD302 is supplied with an eight muscle moving plate assembly and is approved for both Class 4 and 7 testing requirements. In addition, an optional alternative assembly is available housing twelve muscles, providing even more power – half as much again! Both plate assemblies use exactly the same control system and are interchangeable at any time. Technical Specification

- VOSA Approved Class 4 and 7

- Power (Full Load): 230V / 50 Hz / 2A

- Electronics: Microprocessor Controlled

- Maximum Supply Pressure: 7 bar

- Recommended Working Pressure: 6 bar

- Weight and Build – Floor Unit: 45 kg – Steel construction

- Max Design Load: 1500 kg

- Floor Unit Chassis Dimensions 1: 605 x 600 x 45 mm [L x W x H]

- Floor Unit Chassis Dimensions 2: 605 x 600 x 86 mm [L x W x H]

- Control Box Dimensions: 675 x 120 x 150 mm [L x W x H]

- Moving Plate Dimensions and Build: 480 x 330 x 6 mm [L x W x H] – Stainless steel

- Communication: Serial / wireless FM

- Operator Control: Remote hardwired torch / RF torch

- Noise level during operation: <90dB

- Maintenance schedule: 6 months

- Inspection torch and control circuit voltage: 24V